La máquina de fusión a tope operada manualmente se caracteriza por su fácil uso, peso ligero y operación rápida.

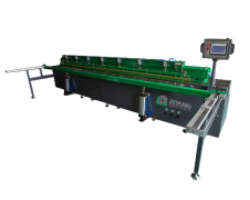

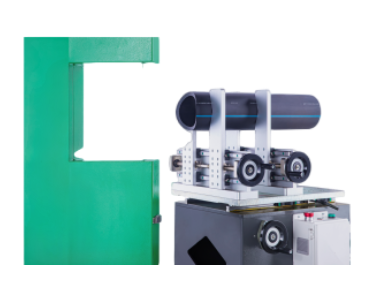

Saddle Radius Saws

Designed for saddle cuts on HDPE, PP, and PVC pipes, this saw delivers precise radial cuts. Its trolley, equipped with a scaled guide, enables quick cutting radius adjustments. The saw rotates electrically during cutting, ensuring safety with a control panel and handles positioned away from the cutting area.

performance

Products Comparison

V160-V355 | V450-V630 | V800-V1200 | |||

| No hydraulic oil system comes as standard | √ | √ | √ | ||

| Saw blade tension adjustment | √ | √ | √ | ||

Laser cut detection | √ | √ | √ | ||

Equipped with saw blade detection device. Once saw blade is broken, machine will stop immediately | √ | √ | √ | ||

Electrically driven adjustable feeding speed | √ | √ | √ | ||

Emergency stop at operation panel | √ | √ | √ | ||

Remote control box with integrated operation buttons, enhancing operator safety | √ | √ | √ | ||

Reviews

Testimonials

Model: ARC 315

"The Riyang cutting saw has significantly improved our pipe fitting production efficiency. The precise radius cutting and stable clamping system ensure accuracy, reducing rework."

faq

Frequently Asked Questions

La máquina de fusión Riyang se ha aplicado en más de 60 países y regiones en los campos de fabricantes de tuberías de polietileno, proyectos de construcción de gas, proyectos de irrigación, instalaciones mineras y civiles, etc. MÁS

Para soporte o cualquier pregunta:

info@riyang-welding.com

llámanos: +86 13588820387